By: Dana Mladin, PRINCIPAL TECHNICAL CONSULTANT, email

Flash point testing is a critical safety evaluation method used to determine the lowest temperature at which a substance can produce flammable vapors in the presence of an open flame or ignition source. This test is essential in assessing the fire hazards associated with various chemicals and flammable materials. Flash point testing helps in identifying potential fire hazards associated with liquids and volatile substances. It enables manufacturers, storage facilities, and users to take necessary precautions to prevent accidents and protect human lives.

Many regulatory agencies, such as Health Canada, OSHA (Occupational Safety and Health Administration) and EPA (Environmental Protection Agency), require flash point data to classify and label chemicals, ensuring compliance with safety regulations. Understanding a substance’s flash point allows for appropriate storage and handling procedures. For example, materials with low flash points may require specialized storage and transportation to minimize fire risks.

Additionally, emergency responders use data from a flash point test to develop effective strategies for handling fires or spills involving flammable materials, minimizing potential harm to both people and the environment. And in some industries, the selection of materials for specific applications often depends on their flash points. This ensures that the chosen substances are compatible with the intended use and do not pose unnecessary fire hazards.

At Dell Tech, we perform flash point testing in our ISO Accredited lab. Continue reading this article for additional information about the standard test methods we offer: ASTM D56 and ASTM D93.

[INSERT_ELEMENTOR id=5883]

Flash Point Tests We Offer

At Dell Tech, we perform the following two methods to test for flash point:

ASTM D56 – Standard Test Method for Flash Point by Tag Closed Cup Tester and,

ASTM D93 – Standard Test Methods for Flash Point by Pensky-Martens Closed Cup Tester

Products We Test

These test methods cover a variety of consumer chemicals such as glass cleaners, hand sanitizers or surface cleaners containing alcohol (eg. ethanol or IPA). We also test workplace chemicals such as lubricants or solvents. Often these products contain one or more chemicals that are flammable and the test will determine if the overall mixture is flammable. This test is designed for substances and mixtures with an expected flash point lower than 93.3°C.

Why Flash Point Testing

This test determines the lowest temperature at which a solvent will produce an ignitable mixture near its surface. The product flash point is required to determine the chemical classification for shipping and labeling (both workplace labels and retail chemical products labels).

Results

Our lab test report provides the flash point of a product. Flash point is required for a flammable liquid classification as required under The Globally Harmonized System of Classification and Labeling of Chemicals (GHS) and Consumer Chemicals and Containers Regulations (CCCR).

What is Flash Point?

Flash point is the lowest temperature (corrected to a standard pressure of 101.3 kPa) at which the application of an ignition source causes the vapours of a liquid to ignite under specified test conditions.

Consumer vs. Workplace Chemicals

Chemical Retail Labels: Consumer Chemicals and Containers Regulations (CCCR) Sections 50 to 52 prescribe ASTM D56 method for solids, paste or gels and liquids with viscosity lower than 5.8 mm2/s at 37.8 C and ASTM D93 for liquids with viscosity higher than 5.8 mm2/s at 37.8 C.

Chemical Workplace Labels: The Globally Harmonized System of Classification and Labeling of Chemicals (GHS) requires that the Flashpoint to be determined by using closed-cup test method.

The Methods: ASTM D56 and ASTM D93

Two of the methods listed in the GHS purple book are ASTM D56 – Standard Test Method for Flash Point by Tag Closed Cup Tester and ASTM D93 – Standard Test Methods for Flash Point by Pensky-Martens Closed Cup Tester.

ASTM D56 test method covers the determination of the flash point using a Tag Closed Cup Tester (see picture below), of a liquid with a low viscosity.

Using a graduated cylinder, 50 mL of the liquid sample is placed in the test cup. Both the cylinder and sample are precooled, if necessary, making sure that the sample temperature at the start of the testing is 27 ± 5°C or at least 10°C bellow the expected flash point, whichever is the lowest. The sample is heated at a slow constant rate. The ignition source is applied at specified intervals and the flash point is the lowest temperature at which application of the ignitions source causes the vapour above the specimen to ignite. The sample is deemed to have flashed when a large flame appears and instantaneously propagates itself over the entire surface of the test specimen. The observed flash point shall be corrected for barometric pressure.

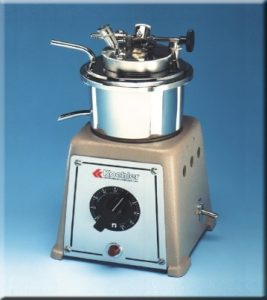

The ASTM D93 standard test method covers the determination of the flash point using a Pensky-Martens Closed Cup Tester (see picture below), of a liquid with a high viscosity or a liquid with tendency to form a surface film under the test conditions.

The ASTM D93 procedure is the same as ASTM D56 with few important differences:

- The test uses 75 mL instead 50 mL of sample

- The sample is stirred at specified rates (90 – 120 r/minute for procedure A and 250 r/min ± 10 r/min) and the stirring is stopped only to apply the ignition source

- The starting temperature of the sample shall be 18°C bellow the expected flash point

Determination of an accurate flash point is important for a compliant classification. A flash point erroneously low can trigger supplementary costs related to packaging, shipping and storage. A flash point erroneously high can determine an incorrect less hazardous classification and implicitly wrong or missing hazards warnings making the product very dangerous for everybody involved in manufacturing, shipping, storing and using the product.

How Dell Tech Can Help

Dell Tech Laboratories is equipped and the staff is trained to perform both ASTM D56 and ASTM D93. Our lab is ISO 17025 accredited. We can help you test and classify your products for GHS, CCCR, or CPSC. We can also help you choose the appropriate test method to classify your product(s).

Additionally, our related services include:

- Other hazard classification testing for consumer & workplace chemicals

- Consultation on requirements under Transportation of Dangerous Goods (TDG) or Department of Transportation (DOT)

- Safety data sheet authoring; GHS requirements for Canada or the USA

- Expertise in consumer chemical product label requirements for Canada, US and Amazon compliance

Dell Tech has provided professional, confidential consulting services to the specialty chemical

industry in Canada, the USA, Europe, and Asia for the last 40 years.

[INSERT_ELEMENTOR id=5705]